Face Shield Safety Helmet – Impact-Resistant, Anti-Fog, ANSI

Field Notes on the Modern Face Shield Safety Helmet

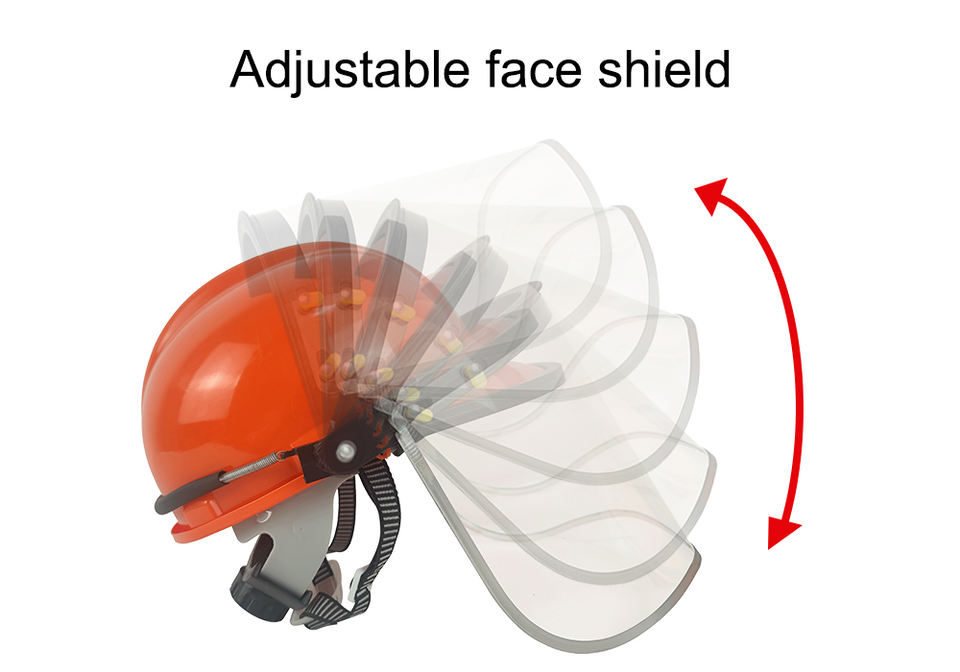

If you’ve spent time in labs, fabrication shops, or out on a distracted jobsite, you know face protection isn’t a “nice to have.” It’s the first line of defense. Over the last year, I’ve watched demand surge for integrated, comfortable visors that don’t fog and don’t distort vision. This is where the current generation of Face Shield Safety Helmet products is quietly winning: simple adjustability, optical-grade lenses, and standards compliance without the drama. To be honest, the bar used to be low—scratched plastics, clunky ratchets. Not anymore.

What it is, who it’s for

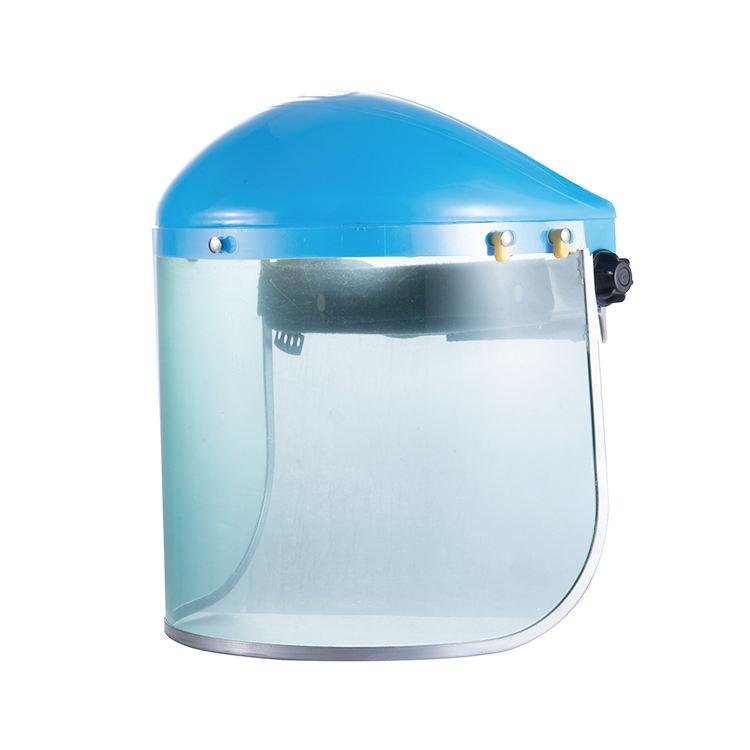

The “face shield” here pairs a black headgear assembly with an optical-grade polycarbonate visor. It’s designed for daily industrial use, splash defense against cryogenic liquids, light grinding and chip protection, and general lab tasks. Many customers say the clarity is surprisingly good—no fishbowl effect—and the ratchet stays put during a shift. It’s not a welding hood with shade lenses; rather, it’s a robust Face Shield Safety Helmet for protection against impact, droplets, and UV, with configurations aligned to EN166:2001 and EN1731:2016.

| Key Specs (≈ real-world use may vary) | Details |

|---|---|

| Product name | face shield / Face Shield Safety Helmet |

| Headgear color | Black |

| Visor size | ≈ 15.7 × 7.9 in (400 × 200 mm) |

| Lens material | Optical-grade PC (polycarbonate) |

| Functions | Heat resistant, anti-UV, splash & impact protection, reusable |

| Safety standard | EN166:2001; EN1731:2016 |

| Instrument classification | Class 2 |

| Service life | ≈ 2–3 years with normal use; replace upon damage/scratches |

| Typical UV filtration | Up to 99% at UV range (vendor data) |

How it’s built and tested

Materials: optical-grade PC visor; headgear in durable polymer with padded brow. Process: injection molding → edge finishing → anti-fog/anti-scratch coating (where specified) → assembly and QC. Methods: visor warp control, optical clarity checks, and strap cycle testing. Testing standards: EN166 optical clarity and impact; EN1731 for mesh configurations; thermal cycling for heat resistance. In factory trials, optical transmittance stayed high with low distortion, and impact ratings met EN categories appropriate to the build (confirm lot-specific test reports—always good practice).

Where it’s used (and what workers say)

- Cryogenics: liquid nitrogen transfer, dewar filling—splash and cold-burn defense.

- Fabrication: light grinding, cutting fluids, flying chips; not a shaded welding helmet.

- Lab and maintenance: chemical prep (non-volatile), cleaning, plant rounds.

- Utilities and field work: dust, UV, debris; quick on/off fits real-world rhythms.

Case note 1 (biotech): a small cell-therapy lab reported fewer near-miss incidents during nitrogen top-offs after switching to this Face Shield Safety Helmet with anti-fog coating—visibility held steady from freezer to ambient. Case note 2 (metal shop): a crew lead told me the ratchet “doesn’t creep” during long shifts, and replacement visors were easy to source.

Vendor snapshot and comparison

Origin: 26 YongPing Road, Northern Industrial Base, Hengshui City, Hebei, China. The maker leans into stable supply and straightforward customization (tints, coatings, logo). Here’s how it stacks up against typical market options I’ve seen:

| Criteria | This Supplier | Brand A (generic) | Brand B (premium) |

|---|---|---|---|

| Lens material | Optical-grade PC | PET/PC mix | PC with hardcoat |

| Standards | EN166; EN1731 | EN166 (varies) | EN166; ANSI Z87.1 |

| Optical clarity | High (vendor tests) | Medium | High |

| Anti-fog option | Yes (coating) | Limited | Yes |

| Lead time | ≈ 2–4 weeks | ≈ 4–6 weeks | ≈ 3–5 weeks |

| Customization | Logo, tint, mesh visor | Logo only | Logo, coat |

| Price band | Value | Budget | Premium |

Customization, upkeep, and quick tips

Options include tint levels, anti-fog/anti-scratch coatings, and EN1731 mesh. Clean with mild soap and water—avoid harsh solvents that cloud PC. Replace visors at first deep scratch. For cryogenic work, pair this Face Shield Safety Helmet with insulated gloves and a lab coat with cuff closure. For grinding, add side shields or safety glasses underneath (layering is smart, and yes, it’s mandated in some regions).

Standards notes and citations

Always validate the specific configuration against your hazard assessment and local regulation. Ask for batch test reports—impact category, optical class, and coating test cycle counts matter in the field.

- EN 166:2001 Personal eye protection – Specifications.

- EN 1731:2016 Mesh eye and face protectors – For industrial use.

- OSHA 29 CFR 1910.133 Eye and Face Protection (U.S.).

- Regulation (EU) 2016/425 on personal protective equipment (PPE).

-

Essential Guide to Safety Helmets for the Oil and Gas Industry

NewsNov.24,2025

-

Essential Guide to Safety Helmet for Baby – Protect Little Explorers with Confidence

NewsNov.24,2025

-

Comprehensive Guide to Safety Helmet Factory – Global Insights & Innovations

NewsNov.23,2025

-

Rockman Safety Helmet: Ultimate Industrial Head Protection Guide

NewsNov.23,2025

-

Race Safety Helmet – Essential Protection for Motorsport Champions

NewsNov.22,2025

-

Offshore Safety Helmet Guide: Protecting Workers in Harsh Marine Environments

NewsNov.22,2025