asi supplier safety clothing factories

The Importance of Safety Clothing in ASI Supplier Factories

In today's industrial landscape, the safety and well-being of employees are paramount. For factories, particularly those associated with ASI (Apparel Supplier Industries), the implementation of appropriate safety clothing is not just a regulatory requirement but a crucial aspect of workplace culture. This article explores the significance of safety clothing in ASI supplier factories, addressing the types of clothing commonly used, the benefits they bring, and best practices for ensuring compliance and awareness.

Understanding Safety Clothing

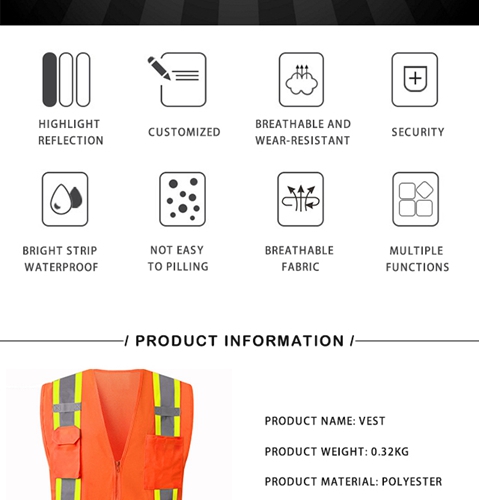

Safety clothing, often referred to as personal protective equipment (PPE), is designed to protect workers from workplace hazards that could cause injuries. In the context of ASI supplier factories, which often involve various levels of risk from machinery, chemical exposure, and other hazards, safety clothing plays a vital role. This includes items like helmets, safety goggles, gloves, high-visibility vests, and specialized clothing such as flame-resistant gear and anti-static suits.

Types of Safety Clothing Used in ASI Factories

1. Protective Footwear Steel-toed boots safeguard workers from heavy objects and provide support during long hours of standing or walking. 2. High-Visibility Apparel For those working in areas with vehicular traffic or heavy machinery, high-visibility vests or jackets are essential to ensure workers are easily seen.

3. Chemical-Resistant Gear In factories where chemicals are handled, specialized clothing that protects against spills or splashes is critical to prevent skin contact and serious injuries.

4. Welding and Flame-Resistant Clothing For tasks involving welding or exposure to flames, flame-resistant clothing helps prevent burns and other related injuries.

5. Respirators and Masks In environments with dust, fumes, or other airborne hazards, respiratory protection is necessary to maintain workers' health.

Benefits of Implementing Safety Clothing

The implementation of safety clothing in ASI factories offers several advantages

- Reduction in Workplace Injuries By wearing appropriate safety clothing, employees are more protected against potential hazards, leading to a significant reduction in workplace injuries and incidents

.asi supplier safety clothing factories

- Increased Awareness The presence of safety gear fosters a culture of safety within the workplace, reminding employees to be vigilant and proactive about their safety and the safety of others.

- Enhanced Productivity When workers feel safe, they are more focused and productive. Safety clothing can also be designed for comfort and mobility, ensuring that employees can perform their tasks effectively without unnecessary hindrance.

- Compliance with Regulations Many regions have strict regulations regarding workplace safety. Providing compliant safety clothing helps factories avoid legal repercussions and potential fines.

Best Practices for Safety Clothing Implementation

To ensure the effectiveness of safety clothing in ASI supplier factories, several best practices should be adopted

1. Regular Training Employees should receive regular training on the importance of safety clothing, how to use it properly, and the specific hazards they may face in their roles.

2. Conduct Risk Assessments Factories should routinely assess potential hazards and ensure that the types of safety clothing provided match those risks.

3. Promote a Safety Culture Encouraging open communication about safety concerns and making it easy for employees to report issues can help cultivate a workplace where safety is prioritized.

4. Regular Maintenance and Replacement Safety clothing can wear out over time. Regular inspections and timely replacements are crucial to ensure that employees are always adequately protected.

5. Involve Employees in Decisions Engaging employees in discussions about safety gear can provide insights into their needs and preferences, fostering a sense of ownership and responsibility towards their safety.

Conclusion

The importance of safety clothing in ASI supplier factories cannot be overstated. These garments are essential for protecting workers, enhancing productivity, and ensuring compliance with safety regulations. By adopting best practices for implementation and fostering a culture of safety, factories can create a safer working environment, ultimately benefiting both employees and the overall success of the organization. Prioritizing safety clothing is not just about adhering to laws but about valuing and protecting the workforce that drives the industry.

-

Top HDPE Safety Helmets - Lightweight, Durable Head Protection

NewsAug.01,2025

-

Top AI Safety Clothing with GPT-4 Turbo | Smart Protection

NewsJul.31,2025

-

Face Shield Safety Helmet with GPT-4 Turbo AI Safety

NewsJul.31,2025

-

CE Working Clothing for Construction & Welding Safety

NewsJul.30,2025

-

Premium Safety Helmet with Visor for Construction & Industrial Use

NewsJul.29,2025

-

High-Quality CE Working Clothing for Safety and Construction

NewsJul.29,2025