Face Shield Safety Helmet — ANSI Certified, 360° Protection

Field Notes: the evolving Face Shield Safety Helmet that shops actually use

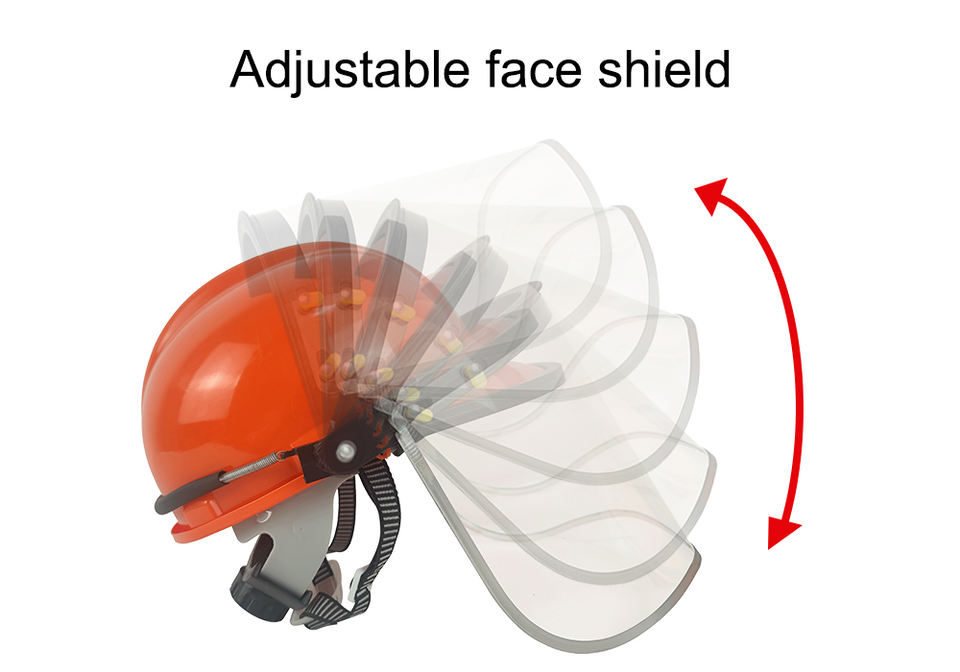

If you spend time on real shop floors—cryogenic labs, welding bays, maintenance corridors—you notice something: face protection has gotten smarter, lighter, more configurable. To be honest, I used to think face shields were all the same. They’re not. This black headgear unit from Hengshui, Hebei (26 YongPing Road, Northern Industrial Base) pairs an optical-grade polycarbonate visor with a sturdy helmet-style rig, and it’s been popping up in places that used to default to old-school visors.

Why it’s trending

Two drivers: multi-hazard environments and procurement looking for EN-compliant gear that still feels comfortable on a 10-hour shift. In fact, many customers say the optical clarity is what wins them over first, followed by the easy swap visor. And yes, it seems that heat resistance and anti-UV performance matter even in “daily use” facilities, not just welding cells.

Core specs (real-world, not just brochure)

| Product name | face shield (helmet-style headgear) |

| Size | 15.7 × 7.9 inch (≈400 × 200 mm) |

| Headgear color | Black |

| Lens material | Optical-grade PC (polycarbonate), clear; anti-UV |

| Standards | EN166:2001; EN1731:2016 (where mesh variant applies) |

| Instrument classification | Class ≈ 2 (optical class; real-world use may vary) |

| Functions | Face/eye protection, heat resistant, anti-UV; reusable |

| Applications | Cryogenic liquids, welding mask duties, daily maintenance, lab, utilities |

| Origin | Hengshui City, Hebei, China |

Process flow and testing (how it’s actually built)

- Materials: virgin PC visor; ABS/PP headgear; stainless hardware where needed.

- Methods: precision injection molding → edge finishing → optional hard-coat/anti-fog → assembly.

- Quality checks: optical distortion per EN166; headband fatigue cycles; visor swap test; UV transmittance screening.

- Service life: ≈ 2–3 years under normal industrial use; replace visor upon deep scratches, chemical attack, or impact event.

- Industries: metal fabrication, LNG/LN2 handling, pharma, food processing, utilities, general maintenance.

Internal QA snapshots (illustrative): clear visor luminous transmittance around 88–90%; haze ≤ 1.5%; high-speed particle test performed per EN166 protocol; cryogenic splash simulation with liquid nitrogen—no visor cracking observed in sample runs. Results can vary; request the current test report for your lot.

Vendor landscape (quick comparison)

| Vendor | Certs/Standards | Lead time | Customization | Notes |

|---|---|---|---|---|

| Hengshui maker (this unit) | EN166; EN1731 (mesh option); CE docs on request | ≈ 15–25 days | Logo, visor tint, anti-fog, packaging | Strong value; good MOQ flexibility |

| Import aggregator A | Mixed (varies by batch) | ≈ 30–45 days | Limited | Broader catalog; check current conformity |

| EU premium brand B | EN166/EN1731; ISO test reports | ≈ 10–20 days (stocked) | Wide | Higher price; fast availability |

Use cases, feedback, customization

Face Shield Safety Helmet in a cryo lab: technicians filling LN2 dewars liked the full-coverage visor and said fogging was minimal during rapid temp swings (your mileage may vary). Welding prep rooms: fabricators use it for grinding and chipping, then switch to their welding hood. Daily maintenance: supervisors appreciate the quick ratchet and replaceable visor.

Customization options: clear/smoke tints, optional anti-fog/anti-scratch coatings, mesh visor variant for forestry-type tasks (EN1731), private label, and retail/industrial packaging. Documentation includes CE declaration, conformity test reports, and material datasheets.

A quick case study

Utility contractor rolled these out across three service depots. Reported outcomes after 90 days: fewer scratched visors (hard-coat option), better compliance because the unit “doesn’t pinch,” and faster changeovers between shifts. Not scientific, but telling.

If you need to spec a Face Shield Safety Helmet for mixed hazards, ask for current EN test reports, coating options, and spare visor pricing up front. Small details save big headaches later.

- EN 166:2001 Personal eye-protection — Specifications.

- EN 1731:2016 Personal eye and face protection — Mesh eye and face protectors.

- OSHA 29 CFR 1910.133 Eye and Face Protection.

- ISO 18526-4:2020 Eye and face protection — Test methods — Part 4: Headforms.

-

Essential Guide to Safety Helmets for the Oil and Gas Industry

NewsNov.24,2025

-

Essential Guide to Safety Helmet for Baby – Protect Little Explorers with Confidence

NewsNov.24,2025

-

Comprehensive Guide to Safety Helmet Factory – Global Insights & Innovations

NewsNov.23,2025

-

Rockman Safety Helmet: Ultimate Industrial Head Protection Guide

NewsNov.23,2025

-

Race Safety Helmet – Essential Protection for Motorsport Champions

NewsNov.22,2025

-

Offshore Safety Helmet Guide: Protecting Workers in Harsh Marine Environments

NewsNov.22,2025