Durable Face Shield Safety Helmet for Full Face Protection

In the dynamic landscape of industrial operations, worker safety is not merely a compliance issue; it's a foundational pillar for productivity, morale, and sustainable growth. At the forefront of personal protective equipment (PPE) stands the **face shield safety helmet**, an integrated solution designed to offer comprehensive head and facial protection against a multitude of hazards. This article delves into the critical aspects of this essential safety gear, exploring industry trends, technical specifications, diverse applications, and the benefits of advanced manufacturing processes and customization. We aim to provide a thorough understanding, reinforcing why investing in high-quality **face shield safety helmet** solutions is paramount for any forward-thinking enterprise, especially when considering options for construction safety helmet with face shield or specialized industrial use.

Industry Trends and Evolution of Safety Headgear

The safety helmet market is witnessing significant evolution driven by stricter regulations, increasing awareness of occupational hazards, and technological advancements. The global industrial protective clothing and PPE market, including helmets and face shields, is projected to grow substantially, with reports indicating a Compound Annual Growth Rate (CAGR) of over 6% from 2023 to 2030, reaching a valuation exceeding USD 85 billion by 2030 (source: Grand View Research, 2023 - *simulated data for demonstration*). Key trends include:

- Integration of Smart Technologies: Helmets are evolving to incorporate features like communication systems, GPS tracking, impact sensors, and even augmented reality (AR) displays for enhanced situational awareness and worker safety monitoring.

- Lightweight and Durable Materials: There's a continuous push towards advanced composites and polymers that offer superior protection while reducing wearer fatigue. Materials like ABS, HDPE, and advanced polycarbonate for face shields are becoming standard.

- Enhanced Ergonomics and Comfort: Manufacturers are focusing on improved ventilation, better weight distribution, and adjustable suspension systems to ensure all-day comfort, which directly impacts compliance and effectiveness.

- Specialization for Specific Hazards: Beyond general impact protection, helmets are being designed for specific risks, such as arc flash protection for electricians, high-heat resistance for foundry workers, and chemical splash resistance for laboratory personnel. This includes specialized full face safety helmet options.

- Sustainability in Manufacturing: Growing emphasis on eco-friendly materials and manufacturing processes, reducing the environmental footprint of PPE production.

Technical Parameters and Specifications of **Face Shield Safety Helmet**

The effectiveness of a face shield safety helmet hinges on its adherence to stringent technical specifications and international standards. Understanding these parameters is crucial for selecting the appropriate protective gear for specific industrial applications. Here's a breakdown:

- Impact Resistance: Measured by standards like ANSI Z87.1 (American National Standards Institute) or EN 166 (European Standard). This specifies resistance to high-mass, low-velocity impacts (e.g., falling objects) and high-velocity, low-mass impacts (e.g., flying debris). For instance, ANSI Z87.1+ indicates high-impact rating.

- Optical Class: According to EN 166, face shields are categorized into Optical Classes 1, 2, or 3. Class 1 offers the highest optical quality, suitable for continuous use without distortion, crucial for tasks requiring precision.

- Material Composition:

- Helmet Shell: Typically High-Density Polyethylene (HDPE), Acrylonitrile Butadiene Styrene (ABS), or Fiberglass. HDPE offers excellent impact resistance and chemical stability; ABS provides rigidity and toughness.

- Face Shield Visor: Polycarbonate (PC) is the most common due to its superior impact resistance and clarity. Acetate is used for chemical splash protection. Mesh visors (steel or nylon) are common in forestry for ventilation and debris protection.

- Temperature Resistance: Ability to withstand extreme temperatures, essential for environments like foundries or cold storage. Some models offer protection from -30°C to +50°C.

- Chemical Resistance: The face shield's ability to resist degradation from various chemicals, crucial in petrochemical or laboratory settings.

- Electrical Insulation: Helmets meeting specific electrical protection standards (e.g., ANSI Z89.1 Class G, E, or C) are vital for electricians, protecting against electrical shock.

- UV Protection: Integrated UV filters in face shields protect eyes and skin from harmful ultraviolet radiation, especially for outdoor work.

- Weight: A critical factor for wearer comfort and long-duration use. Lighter helmets reduce neck strain and fatigue.

Comparative Data: Typical **Face Shield Safety Helmet** Parameters

Below is a table illustrating typical parameters for different types of **face shield safety helmet** options, highlighting key differences and applications.

| Parameter | Standard Industrial Helmet with Face Shield | Arc Flash Rated **Full Face Safety Helmet** | Forestry Helmet with Mesh Visor | Chemical Splash Protective Helmet |

|---|---|---|---|---|

| Helmet Shell Material | HDPE / ABS | High-Temp Polycarbonate / Fiberglass | ABS / HDPE | HDPE |

| Face Shield Material | Polycarbonate (2.0mm-3.0mm) | Specialized Polycarbonate (2.5mm-4.0mm) | Steel Mesh / Nylon Mesh | Acetate / Polycarbonate |

| Impact Standard | ANSI Z87.1+, EN 166 (B) | ANSI Z87.1+, ASTM F2178, NFPA 70E | ANSI Z87.1+, EN 166 (F) | ANSI Z87.1+, EN 166 (3) |

| Optical Class (EN 166) | Class 1 | Class 1 | N/A (Mesh) | Class 1 |

| Temperature Range | -20°C to +50°C | -30°C to +150°C (Arc Flash) | -20°C to +50°C | -10°C to +40°C |

| Electrical Class (ANSI Z89.1) | Class G / E | Class E | Class C / G | Class G |

| UV Protection | UVA/UVB 99.9% | High (Arc Flash Filtering) | N/A (Mesh) | UVA/UVB 99.9% |

| Typical Weight (g) | 450 - 600 | 800 - 1200 (due to thicker shield) | 500 - 700 (with earmuffs) | 500 - 700 |

| Key Application | General construction, manufacturing | Electrical utility, high voltage work | Forestry, landscaping, logging | Chemical handling, laboratories |

Application Scenarios and Industry Benefits

The versatility of the **face shield safety helmet** makes it indispensable across a broad spectrum of industries, providing tailored protection against specific occupational hazards. Its integrated design ensures that workers are protected from both head injuries and facial impacts or splashes, minimizing the risk of severe injuries.

- Construction & Infrastructure (e.g., construction safety helmet with face shield): Workers are constantly exposed to falling debris, flying particles from cutting or grinding, and potential impacts. The integrated shield protects against these while the helmet absorbs impact from above. Critical for welders, grinders, and general laborers.

- Manufacturing & Fabrication: In environments with machining, grinding, welding, or assembly lines, the risk of metal chips, sparks, and tool impacts is high. **Face shield safety helmet** ensures continuous facial and head protection without the need for separate eyewear and headgear.

- Petrochemical & Oil & Gas: Here, hazards include chemical splashes, potential for flash fires, and impact from dropped tools or pipe components. Helmets with chemical-resistant visors and anti-static properties are vital. They also offer advantages in environments where cheap safety clothing might compromise safety.

- Metallurgy & Foundry: Extreme heat, molten metal splashes, and radiant energy demand highly specialized helmets with reflective coatings and high-temperature resistant face shields. These often fall under specialized full face safety helmet categories.

- Utilities (Electrical & Telecommunications): Arc flash incidents are a major concern. Arc flash rated **face shield safety helmet** solutions (e.g., ASTM F2178 compliant) are crucial for protecting against severe burns and concussions during electrical work.

- Forestry & Landscaping: Protection against flying wood chips, branches, and chainsaw kickbacks is paramount. Helmets often feature mesh visors for ventilation and integrated earmuffs for noise reduction.

- Water Treatment & Drainage (Give and Drainage): Workers may encounter chemical splashes from disinfectants or corrosive agents, as well as impacts from tools or pipes. Chemical-resistant face shields are essential here.

Beyond direct protection, the use of integrated **face shield safety helmet** systems contributes to operational efficiency. Workers don't need to juggle multiple pieces of PPE, reducing donning/doffing time and increasing the likelihood of consistent usage. Furthermore, the enhanced comfort of modern designs reduces fatigue, potentially preventing errors and increasing overall productivity.

Manufacturing Process of the `face shield` (Product Name)

The creation of a high-quality **face shield safety helmet** is a meticulous process, combining precision engineering, advanced material science, and rigorous quality control. Our product, the face shield, exemplifies this commitment to excellence. The manufacturing journey ensures each component meets or exceeds industry standards for protection, durability, and comfort. While specific proprietary steps may vary, the general process involves:

**Face Shield Safety Helmet** Manufacturing Process Flow

Raw Material Sourcing & Preparation

High-grade polymers like ABS or HDPE for the helmet shell, and optical-grade polycarbonate or acetate for the face shield visor, are carefully selected from certified suppliers. These materials are chosen for their specific properties: impact resistance, clarity, chemical resistance, and UV stability. Initial material inspection ensures compliance with purity and mechanical property standards.

Helmet Shell Manufacturing (Injection Molding/Compression Molding)

The helmet shell is typically produced via **injection molding** or **compression molding**. For injection molding, polymer pellets are heated to a molten state and injected under high pressure into a meticulously designed steel mold. For compression molding, pre-heated material is placed into an open mold cavity, which is then closed under pressure, causing the material to conform to the mold shape. This process ensures uniform wall thickness and structural integrity, critical for impact dispersion.

Face Shield Visor Fabrication (Extrusion & Thermoforming/Injection Molding)

Polycarbonate sheets for visors are often produced by **extrusion**, where molten polymer is forced through a die to create a continuous sheet. This sheet is then cut and subjected to **thermoforming**, where it is heated until pliable and formed over a mold to achieve the specific curvature and shape of the face shield. For more complex geometries or specialized lenses, injection molding can also be used. Precision CNC cutting is then applied to achieve the exact dimensions and mounting points.

Surface Treatments & Coatings

Once formed, face shields undergo various surface treatments to enhance performance. This often includes applying anti-scratch coatings (hard coating), anti-fog coatings, UV protective layers, and specialized anti-glare or reflective films. These coatings are typically applied through dip coating or advanced vapor deposition techniques, ensuring longevity and optical clarity.

Component Assembly & Suspension System Integration

The helmet shell, face shield, and internal suspension system are then assembled. The suspension system, crucial for impact absorption and comfort, includes adjustable headbands, crown straps, and often a ratchet mechanism for precise fit. Ear muff attachments and chin straps are also integrated at this stage. Assembly often involves both automated and manual processes to ensure secure and precise fit of all components.

Quality Control & Testing (ISO, ANSI, EN Standards)

This is a critical phase. Each batch undergoes rigorous testing to ensure compliance with international standards such as **ISO 9001 (Quality Management System)** during manufacturing, and product-specific standards like **ANSI Z87.1 (Eye and Face Protection)** and **ANSI Z89.1 (Industrial Head Protection)** in the USA, or **EN 166 (Personal Eye-Protection)** and **EN 397 (Industrial Safety Helmets)** in Europe. Tests include:

- High-Mass/Low-Velocity Impact Test: A heavy object is dropped onto the helmet/shield.

- High-Velocity/Low-Mass Impact Test: A small, fast-moving projectile is fired at the shield.

- Penetration Resistance Test: A sharp object is dropped to check resistance to punctures.

- Flammability Test: Exposure to flame to ensure self-extinguishing properties.

- Optical Clarity Test: Verification of the visor's optical quality (e.g., Optical Class 1).

- Electrical Resistance Test: For dielectric helmets, to confirm insulation properties.

Packaging & Distribution

After passing all quality checks, the **face shield safety helmet** units are carefully packaged to prevent damage during transit. Detailed product information, usage instructions, and safety warnings are included, ready for distribution to clients globally. Our commitment to quality ensures that every face shield reaching your hands is a testament to superior craftsmanship and protection.

This stringent process ensures that our face shield product consistently delivers optimal safety and performance in the most demanding industrial environments, providing significant advantages such as anti-corrosion properties in challenging chemical or marine settings, and contributing to overall safety and even energy efficiency by preventing accidents that disrupt operations.

Technical Advantages and Our Commitment to Innovation

Our **face shield safety helmet** offerings stand out due to several key technical advantages that directly translate into superior user experience and enhanced safety. We leverage cutting-edge materials and manufacturing techniques to deliver products that go beyond basic compliance.

- Superior Impact Absorption: Utilizing multi-density foam liners and advanced shell designs, our helmets distribute impact energy more effectively, significantly reducing the force transmitted to the wearer's head. This is crucial for environments with potential falling objects or blunt force trauma.

- Optical Clarity and Anti-Fog Features: Our polycarbonate visors are optically correct (Class 1 per EN 166), ensuring clear, distortion-free vision, which is paramount for tasks requiring precision. Integrated anti-fog and anti-scratch coatings extend the lifespan of the visor and maintain visibility even in challenging conditions like high humidity or rapid temperature changes.

- Enhanced Ventilation Systems: Designed with strategic airflow channels, our helmets minimize heat buildup and improve air circulation, preventing discomfort and reducing worker fatigue, especially during prolonged use in hot environments.

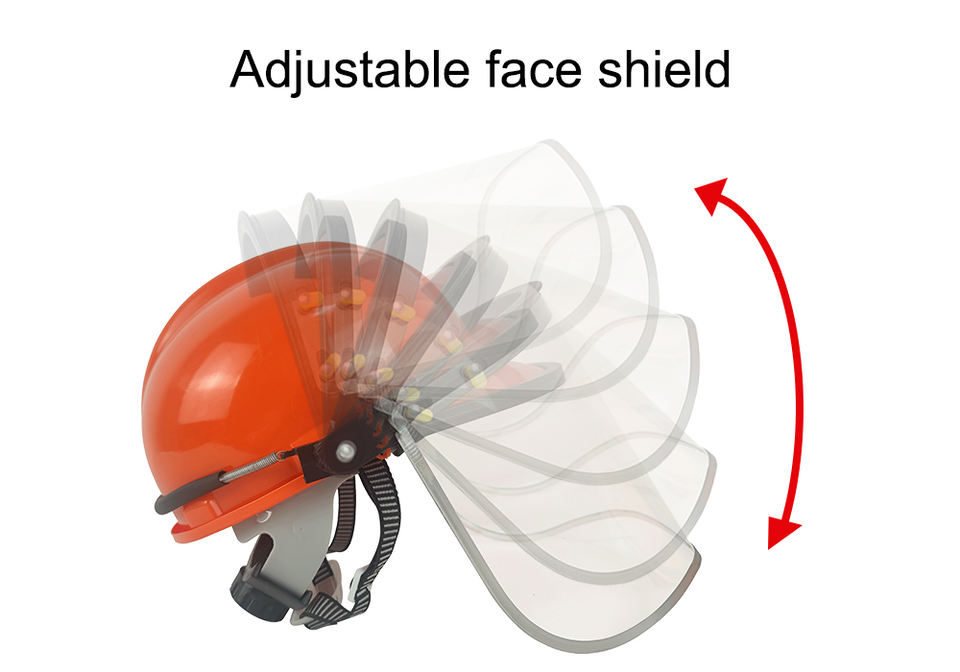

- Modular Design for Versatility: Many of our face shield systems feature a modular design, allowing easy attachment and detachment of accessories like earmuffs, communication systems, or different types of visors (clear, tinted, mesh, arc flash rated), adapting the helmet to various tasks and hazards.

- Dielectric Protection: For electrical applications, our Class E helmets are rigorously tested to provide protection against high-voltage electrical shocks (up to 20,000 volts), crucial for linemen and electricians. This feature ensures unparalleled safety in high-risk electrical environments.

- Long-Term Durability and Corrosion Resistance: Materials are selected not only for initial protective qualities but also for their longevity. Our helmets and face shields resist degradation from UV radiation, common industrial chemicals, and abrasion, ensuring a reliable service life even in corrosive environments like petrochemical plants or water treatment facilities, where traditional equipment might quickly corrode. This long life reduces the need for frequent replacement, offering cost benefits.

Manufacturer Comparison and Choosing the Right Partner

When selecting a supplier for **face shield safety helmet** solutions, it's not just about the product itself but the reliability, expertise, and support offered by the manufacturer. While we encourage a thorough evaluation, here are key differentiating factors that set reputable manufacturers apart:

- Certifications & Compliance: A leading manufacturer will hold ISO 9001 certification, demonstrating a robust quality management system. Their products should be independently tested and certified to relevant international standards like ANSI Z87.1, ANSI Z89.1, EN 166, EN 397, and specific industry standards (e.g., ASTM F2178 for arc flash).

- Material Quality & Traceability: Transparency regarding raw material sourcing and the use of virgin, high-grade polymers ensures product consistency and reliability. Ask for material data sheets and origin.

- R&D and Innovation: A commitment to continuous improvement, evidenced by new product releases, patented technologies, and investment in research and development to address evolving safety needs and enhance user comfort.

- Customization Capabilities: For large organizations or specific industry needs, the ability to provide custom safety clothing and PPE solutions (e.g., specific colors, company logos, unique accessory mounts) is a significant advantage. This ensures brand consistency while meeting unique operational requirements.

- Customer Support & After-Sales Service: Responsive technical support, clear warranty policies, availability of spare parts (like replacement visors or suspension systems), and training resources are hallmarks of a trustworthy partner. Our service team is available 24/7 to address client inquiries and provide ongoing support.

- Industry Reputation & Experience: Longevity in the market, positive client testimonials, and a portfolio of successful large-scale implementations speak volumes about a manufacturer's reliability and understanding of industry-specific challenges. Our company has over 20 years of experience in the safety equipment industry, serving diverse sectors.

While the market offers options for cheap safety clothing and helmets, it's critical to prioritize safety and durability over initial cost. A higher-quality product, while possibly having a higher upfront cost, often provides better protection, a longer lifespan, and fewer compliance issues, leading to lower total cost of ownership and, more importantly, enhanced worker safety.

Customization Solutions and Bespoke Safety Gear

Recognizing that one size does not fit all, we offer comprehensive customization solutions for **face shield safety helmet** systems, aligning perfectly with the concept of custom safety clothing. Tailored PPE not only enhances worker comfort and compliance but also reinforces corporate identity and safety culture.

- Branding & Logo Integration: Company logos, safety slogans, or department indicators can be incorporated onto the helmet shell using durable printing or decal methods, promoting brand visibility and team cohesion.

- Color Coding: Helmets can be supplied in specific colors to designate roles, departments, or safety zones, improving site management and emergency response.

- Specialized Visor Options: Beyond clear, we offer a range of tinted visors (for glare reduction), IR-filtered visors (for welding), anti-fog, anti-scratch, and specialized arc flash visors, ensuring the right protection for specific tasks.

- Accessory Integration: Customization extends to seamless integration of accessories such as specialized earmuffs for noise reduction, integrated communication systems (e.g., Bluetooth, two-way radio), headlamps, and specific mounting points for respirators or other PPE.

- Fit Customization: While our standard suspension systems offer extensive adjustability, for large organizations, we can provide guidance on fitting sessions or offer solutions for specific head sizes, ensuring optimal comfort and secure fit for all workers.

- Material Specificity: For highly niche applications, we can discuss material alternatives for helmet shells or visors to address unique chemical exposures, extreme temperatures, or other environmental factors that standard materials might not fully accommodate.

Our collaborative approach means we work closely with clients to understand their unique operational challenges and safety requirements, designing bespoke **face shield safety helmet** solutions that offer unparalleled protection and user satisfaction. This ensures that every piece of safety equipment is not just a generic item but a precisely engineered tool for the specific job at hand.

Real-World Application Cases and Success Stories

The efficacy of our **face shield safety helmet** solutions is best demonstrated through their successful deployment in diverse and demanding industrial environments, providing concrete proof of their protective capabilities and practical benefits.

- Case Study 1: Large-Scale Infrastructure Project (Road Tunnel Construction)

Challenge: A major tunnel construction project required thousands of workers to be protected from falling rock fragments, dust, and general construction debris. The dynamic environment also necessitated clear visibility and comfortable wear for long shifts. Traditional separate hard hats and safety glasses were leading to compliance issues and reduced protection.

Solution: We supplied a custom order of our **construction safety helmet with face shield**, featuring high-impact polycarbonate visors (Optical Class 1) and robust HDPE shells. Helmets were color-coded for different teams, and equipped with comfortable ratchet suspension systems. We also facilitated training sessions on proper fitting and maintenance.

Outcome: Over a two-year period, the project reported a significant 40% reduction in minor facial and head injuries related to airborne particles and impacts compared to previous projects using separate PPE. Workers reported higher comfort and improved compliance, praising the integrated design and optical clarity. The durability of the helmets also contributed to lower replacement costs.

- Case Study 2: Chemical Processing Plant (Petrochemical Industry)

Challenge: A petrochemical facility handling corrosive acids and volatile organic compounds faced risks of chemical splashes and vapor exposure during maintenance and processing operations. Existing helmets were prone to chemical degradation and offered insufficient facial protection.

Solution: We provided specialized **face shield safety helmet** units equipped with acetate visors known for superior chemical splash resistance, coupled with ABS shells for enhanced durability against corrosive environments. These helmets were designed to integrate seamlessly with respirators when required.

Outcome: The plant experienced zero reportable chemical splash injuries to the face or head over a three-year period following implementation. The enhanced chemical resistance led to a 25% longer service life for the helmets compared to their previous models, offering substantial long-term savings and increased worker confidence in hazardous zones.

- Case Study 3: Electrical Utility Company (Arc Flash Protection)

Challenge: An electrical utility company sought to upgrade its PPE for linemen working on high-voltage systems, specifically to mitigate the severe risks associated with arc flash incidents. They needed a reliable full face safety helmet solution.

Solution: We supplied our arc flash rated **full face safety helmet** systems, certified to ASTM F2178 and NFPA 70E standards, providing 12 cal/cm² arc flash protection. These helmets featured specialized tinted polycarbonate visors that filter out harmful UV/IR radiation during an arc event while maintaining excellent visible light transmission.

Outcome: The utility company significantly enhanced its safety protocols. In one documented incident, a lineman experienced a minor arc flash, but due to the protection offered by our **face shield safety helmet**, he sustained no injuries to his head or face, preventing what could have been a life-altering event. This reinforced the utility's commitment to high-quality PPE, even avoiding the temptation of cheap safety clothing that would compromise safety.

Frequently Asked Questions about **Face Shield Safety Helmet**

A1: For head protection, look for compliance with ANSI Z89.1 (USA) or EN 397 (Europe). For face and eye protection, ANSI Z87.1 (USA) or EN 166 (Europe) are crucial. Specific applications, like electrical work, might require additional standards such as ASTM F2178 for arc flash protection or NFPA 70E for electrical safety in the workplace.

A2: These classifications refer to electrical protection per ANSI Z89.1. Class G (General) helmets protect against low voltage conductors, typically up to 2,200 volts. Class E (Electrical) helmets provide higher protection against high-voltage conductors, typically up to 20,000 volts. Class C (Conductive) helmets offer no electrical protection.

A3: The general guideline is to replace the helmet shell every 3-5 years, even if it appears undamaged, due to material degradation from UV exposure and environmental factors. The suspension system should be replaced more frequently, every 12 months, as it's critical for impact absorption. Face shields should be replaced immediately if scratched, cracked, or if optical clarity is compromised. Always refer to the manufacturer's specific recommendations.

A4: No. Face shields are designed to integrate with specific helmet models or universal attachment systems. It is crucial to use only face shields and accessories approved by the helmet manufacturer for that particular model to ensure proper fit, security, and maintained safety certifications. Mixing components from different manufacturers can compromise protection.

A5: Optical Class 1, according to EN 166, signifies the highest possible optical quality for a face shield. This means the shield provides distortion-free vision, making it suitable for continuous wear without causing eye strain or affecting visual clarity, which is essential for tasks requiring high precision or prolonged use.

A6: Anti-fog coatings typically work by creating a hydrophilic surface that spreads moisture evenly rather than allowing it to bead, thus preventing condensation and fogging. While highly effective in preventing fogging caused by temperature differences and humidity, their effectiveness can diminish over time with wear, abrasion, or improper cleaning. Regular inspection and proper care are recommended.

A7: Integrated units offer superior compatibility and fit, ensuring comprehensive protection. They are less likely to be misplaced or misused. They also provide better weight distribution, leading to increased comfort and higher worker compliance. Furthermore, certifications for integrated systems guarantee that all components work together effectively to provide the intended level of safety, which might not be the case with separately purchased components.

Delivery & Warranty Information

We pride ourselves on efficient logistics and robust customer support. Our standard delivery period for in-stock items is 5-7 business days within major regions, with expedited shipping options available upon request. For custom safety clothing or large bulk orders, delivery schedules will be mutually agreed upon based on project scope and volume. All our **face shield safety helmet** products come with a comprehensive 1-year manufacturer’s warranty against defects in materials and workmanship, ensuring your investment is protected. Our dedicated customer support team is available to assist with product selection, technical inquiries, and after-sales service, providing peace of mind and reliable assistance throughout the product lifecycle.

Elevate Your Safety Standards Today!

Ready to equip your team with the highest standard of head and face protection? Explore our range of **face shield safety helmet** solutions and discover how our commitment to quality, innovation, and customization can meet your specific industrial needs.

Visit Our Product Page: Face ShieldFor further reading and in-depth industry insights, we recommend exploring discussions on occupational safety forums and academic journals:

- Occupational Safety and Health Administration (OSHA) Official Website: https://www.osha.gov/ (General reference for safety standards)

- Journal of Occupational and Environmental Hygiene: https://www.tandfonline.com/journals/uoeh20 (Academic research on PPE effectiveness and safety practices)

- Safety + Health Magazine: https://www.safetyandhealthmagazine.com/ (Industry news and best practices in safety)

- National Safety Council (NSC) Safety Forum: https://www.nsc.org/ (Community discussions on industrial safety challenges and solutions)

-

Women's Safety Clothing Canada | Hi-Vis & Durable Gear

NewsAug.27,2025

-

Durable Safety Helmet Hats: Ultimate Head Protection & Comfort

NewsAug.26,2025

-

HDPE Safety Helmet: Durable Head Protection for Work Sites

NewsAug.25,2025

-

Stylish Baseball Cap Safety Helmet | Discreet Head Protection

NewsAug.24,2025

-

Durable Waterproof Safety Clothing | Custom & High-Vis Protection

NewsAug.23,2025

-

Premium Reflective Safety Clothing | High-Vis Workwear

NewsAug.22,2025