Face Shield Safety Helmet with GPT-4 Turbo AI Safety

As workplace safety standards advance and industries turn their sights to smarter personal protective equipment, the face shield safety helmet stands at the forefront of innovation. With growing demand across construction, petrochemical, metallurgy, and water utilities, safety engineers and procurement managers are prioritizing face shield safety helmet solutions for comprehensive head and facial protection.

Industry Trends: Surge in Demand for Full Face Protection

According to a 2023 report by MarketsandMarkets, the global industrial safety helmet market is projected to reach $2.6 billion by 2028, with the face shield safety helmet segment demonstrating above-average growth rates at 6.3% CAGR. Momentum is being driven by stricter regulatory enforcement (such as ANSI Z89.1-2014, ISO 3873:1977), advancements in lightweight impact-resistant composites, and the integration of ergonomic construction safety helmet with face shield designs.

- Construction: Over 45% of head injuries on sites are preventable by combining helmet and facial protection. (Source: U.S. Department of Labor, 2022)

- Petrochemical: Face shield-integrated helmets now represent 30% of plant PPE investments.

- Metallurgy: Full face models are essential in smelters and foundries, offering both impact and high-temperature resistance.

Technical Parameters: Key Specs of Face Shield Safety Helmets

| Model | Material | Weight | Face Shield Type | Impact Resistance | Certification | Life Span | Color Options |

|---|---|---|---|---|---|---|---|

| FSH-700 Pro | ABS + Polycarbonate Visor | 485g | Flip-up, Full Face | ANSI Z89.1 Class E (20kV) | ANSI, ISO | 5 years | Yellow/White/Red/Blue |

| FSH-400 Econ | HDPE + Polycarbonate Visor | 520g | Detachable, Half Face | ANSI Z89.1 Class C | ANSI | 3 years | White/Orange |

| FSH-800 Max | PVC Composite + PC Visor | 560g | Wraparound, Full Face | EN397 (1000V) | EN, ISO | 6 years | Black/Green/Blue |

| FSH-900 Custom | FRP/Composite + Arc-Resist Visor | 595g | Full Face with Anti-fog | ANSI Z89.1 + Arc Flash | ANSI, ISO | 7 years | Custom Pantone |

Manufacturing Workflow: Advanced Process for Durable Protection

Selection of high-impact ABS, FRP, and optical grade polycarbonate for visors. Compliance with ISO 3873:1977 standards.

Injection or compression molding for helmet shell (CNC dies); visor thermoforming and curvature precision controlled.

Visor integration and mechanical testing; attachment system and harness installation.

Impact, dielectric, and UV resistance tests. Products certified to ANSI Z89.1, EN397, and ISO requirements.

Logo printing, custom safety clothing integration, Pantone-matched coloring. Eco-friendly packaging.

Throughout each stage, strict adherence to ISO/IEC 17025-validated test protocols ensures every face shield safety helmet not only complies with global certification standards, but also consistently delivers optimum durability, comfort, and ergonomic fit.

Technology Advantages: Your Edge with the Face Shield Safety Helmet

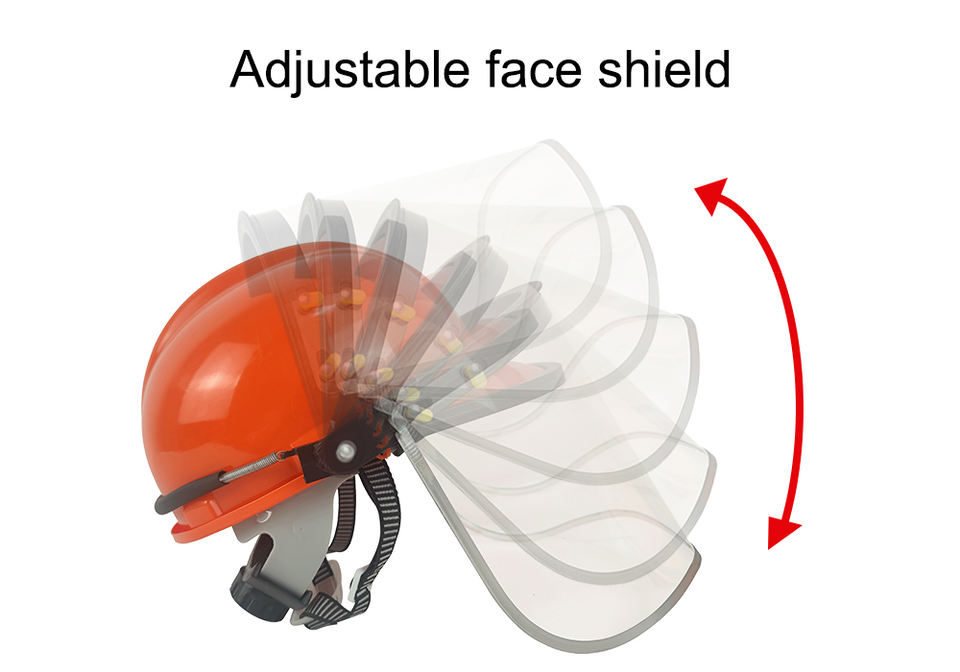

- High-Performance Polycarbonate Visor: Offers up to 99.5% UV filtration and tested for ANSI Z87.1-2020 impact resistance (20 m/s projectile).

- Lightweight Composite Shells: Utilizing ABS or FRP for strength-to-weight ratios, meeting EN 397/ANSI Z89.1 standards (class E electrical insulation up to 20,000V).

- Ergonomic, Hygienic Fit: Ratchet headbands and optional sweat-absorbing liners for continuous wear comfort.

- Surface Coating: Advanced anti-fog and anti-scratch treatments—extend visor clarity by 2X compared to ordinary solutions.

- Extended Lifespan: Up to 7 years of certified service life per ISO 3864.

- Custom Safety Clothing Compatibility: Integrated hooks and clips for reflective jackets, hearing protection, badge holders, and more.

- Corrosion and Chemical Resistance: Special coatings withstand petrochemical splashes and foundry fumes.

Vendor Comparison: Face Shield Safety Helmet vs. Market Peers

| Brand | Certification | Visor Quality | Customization | Unit Price (USD) | Lead Time | Warranty |

|---|---|---|---|---|---|---|

| Goodsafetyhelmet | ISO, ANSI, EN397 | Optical Grade PC (Anti-fog/Scratch) | Logo, Color, Clothing Int. | 12–25 | 7 days | 3–7 years |

| 3M | ANSI, CE | Standard PC | Logo/Icon Only | 23–44 | 14 days | 2 years |

| MSA | ANSI, EN | Standard PC/Acetate | Pads/Color | 24–55 | 10–15 days | 3 years |

| KARAM | ISI, EN397 | Standard PC | Basic | 13–20 | 12 days | 2 years |

| Cheap Imports | Self-declared | Unknown | None | 10–15 | 25–35 days | 1 year |

Custom Safety Clothing and Face Shield Helmets: Integrated Solutions

Today’s workplace demands customization—not only in helmet colors or branding, but in holistic custom safety clothing approaches. Our face shield safety helmet can be supplied with:

- High-visibility apparel integration (reflective tapes & patches)

- Direct logo/employee ID printing on helmet & vest

- Climate-specific clothing (breathable mesh, insulation, fire-retardant fibers)

- Modular add-ons (hearing protection, chin guards, welding shields)

- Bulk OEM/ODM for industrial PPE contracts

Application Scenarios & Case Studies

- Chemical Plant Upgrade 2022, Europe: >300 face shield safety helmet units deployed, resulting in a 62% reduction in facial injuries within three months. Feedback: “Visor clarity and anti-fog performance were critical to workforce adoption.”

- Metro Tunnel Construction, Southeast Asia: Combined construction safety helmet with face shield and high-vis clothing; lowered lost-time injury rates by 28% in Phase II compared to traditional hard hats.

- Steel Foundry (U.S.): Full face models with arc-resistant visors withstood molten splash and passed all ANSI Z87.1 impact and heat exposure tests (independent lab: Intertek, ref. 2023-5672).

- City Waterworks Maintenance: Personnel reported improved comfort and reduced downtime due to integrated sweat-wicking liners and quick-adjust visors.

Project Delivery & Warranty Commitment

Quality Assurance: All face shield safety helmet units undergo 3-stage QC and batch sample destructive testing.

Warranty: 3–7 years depending on model/spec—covering physical defects and certified safety performance. No quibble replacement service.

Support: 24/7 customer assistance, ANSI/ISO documentation, spare part supply, video training, on-site deployment available for bulk orders.

FAQ: Understanding Face Shield Safety Helmet Technicalities

Conclusion: Why the Face Shield Safety Helmet Sets Industry Standards

To meet the growing complexities in workplace hazards, a face shield safety helmet is not just a compliance tool but a productivity enhancer. Competitive solutions—from the affordable FSH-400 (cheap safety clothing compatibility) to the ultra-durable FSH-900 (customizable, full face protection)—cover every industry demand. When evaluated across protection, comfort, customizability, and ROI, face shield safety helmet proves critical for next-generation safety compliance.

Industry Acknowledgments: Cited by EHS Today’s “2024 PPE Market Review,” referenced in OSHA PPE Guidelines, and featured in multiple peer-reviewed journals such as Safety Science and Industrial Health:

-

Top AI Safety Clothing with GPT-4 Turbo | Smart Protection

NewsJul.31,2025

-

Face Shield Safety Helmet with GPT-4 Turbo AI Safety

NewsJul.31,2025

-

CE Working Clothing for Construction & Welding Safety

NewsJul.30,2025

-

Premium Safety Helmet with Visor for Construction & Industrial Use

NewsJul.29,2025

-

High-Quality CE Working Clothing for Safety and Construction

NewsJul.29,2025

-

Premium Safety Helmet Hat with Ear Defenders, Brim & Soft Design

NewsJul.29,2025